Anti-Static Carbon Core Filament Yarns Market to Reach USD 3.0 billion by 2036 as Compliance and Automation Drive Demand

The Anti-Static Carbon Core Filament Yarn Market is shifting from niche to compliance-critical, driven by automation, ESD rules, and low-carbon materials demand

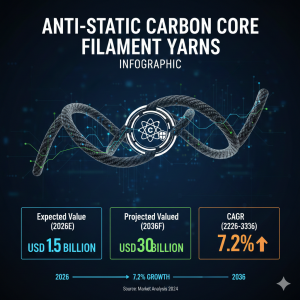

NEWARK, DE, UNITED STATES, February 6, 2026 /EINPresswire.com/ -- The global anti-static carbon core filament yarn market is entering a structurally accelerated growth phase, with market value expected to reach USD 1.5 billion in 2026 and further expand to USD 3.0 billion by 2036, advancing at a CAGR of 7.2%. What was once a specialized industrial input is rapidly evolving into a compliance-critical material platform, anchored in automation, electrification, and sustainability mandates reshaping global manufacturing.

Unlike earlier growth cycles driven by optional performance enhancements, demand in 2026 is increasingly shaped by regulatory exposure, yield protection, and auditability. Industries ranging from semiconductor manufacturing to electrified mobility now treat electrostatic discharge (ESD) control as an enforceable operational requirement rather than a discretionary upgrade. This shift is fundamentally altering procurement behavior and long-term supplier relationships.

The competitive landscape reflects this realignment. Large Western conglomerates are simplifying portfolios, exiting diversified materials segments to concentrate on high-value control points. Honeywell’s separation into focused automation and aerospace entities, alongside its 2025 spin-off of Solstice Advanced Materials, mirrors a broader industry trend toward specialization, pricing discipline, and deeper R&D alignment with regulated end markets.

This narrowing of strategic focus is enabling intensified innovation in applications where ESD failure carries asymmetric financial risk. Semiconductor cleanrooms, EV battery housings, and advanced electronics increasingly justify premium pricing for intrinsically conductive carbon-core filament systems that deliver permanent conductivity and lifecycle stability.

Sustainability has emerged as a structural mandate rather than a marketing differentiator. The 2025 launch of Teijin’s Tenax Next™, delivering a 35% reduction in CO₂ emissions while maintaining electrical conductivity, has established a new benchmark for low-carbon performance. Such innovations align closely with the EU Digital Product Passport rollout beginning in 2026, which mandates full material traceability, lifecycle transparency, and verified carbon metrics across technical textile supply chains.

Asian manufacturers are scaling aggressively in response to regulatory convergence. Kolon Industries’ expansion of aramid pulp capacity, aligned with Euro 7 automotive compliance, underscores how market leadership is increasingly defined by the ability to solve complex regulatory challenges at industrial scale rather than by volume alone.

From a strategic standpoint, the market has moved beyond incremental performance gains toward systemic optimization. As noted by Jörg Friedrich, CTO of Teijin Carbon Europe, the convergence of performance, circularity, and process efficiency is redefining competitive advantage. Carbon core filament yarns are now evaluated as long-term compliance platforms embedded into production ecosystems, not interchangeable textile inputs.

Market Outlook and Key Takeaways

• Market value (2026E): USD 1.5 billion

• Market value (2036F): USD 3.0 billion

• CAGR (2026–2036): 7.2%

Electronics and semiconductor manufacturing anchor demand stability, accounting for approximately 41% of end-use consumption. In these environments, antistatic textiles function as part of process risk management. Once qualified, yarn platforms remain locked into production for extended periods, reinforcing recurring demand and long-term contracts.

On the material side, conductive carbon fiber accounts for nearly 42% of total demand due to its predictability and compatibility with existing industrial standards. Procurement teams prioritize repeatability and resistivity stability over headline performance gains, making carbon-core architectures difficult to displace once specified.

Broader forces continue to reinforce market momentum. Euro 7 automotive regulations, stricter non-exhaust emission limits, expansion of sub-5nm semiconductor nodes, and regional industrial policy are collectively raising barriers to entry. These dynamics favor suppliers with electro-functional precision, qualification depth, and documented sustainability credentials.

Geographically, growth remains broadly distributed. The United States is re-sorting its high-performance fiber industry around capital discipline and specialization, advancing at a 7.0% CAGR. China, at 6.8% CAGR, is elevating advanced fibers as strategic industrial enablers under its 15th Five-Year Plan, prioritizing domestic substitution and ecosystem control. Japan continues to optimize for returns and application specificity, while India and South Korea are strengthening localized capacity supported by policy incentives and export alignment.

Competitive dynamics are increasingly shaped by traceability, circular feedstocks, and regionalized supply chains rather than scale alone. As surface-treated antistatic fibers fail durability and wash-fastness requirements, intrinsically conductive carbon-core systems are becoming baseline qualifications across aerospace, cleanrooms, and electrified mobility.

Looking ahead, success through 2027 will depend on integrating recycled inputs, validating lifecycle data, selectively localizing production, and maintaining cost discipline in an increasingly regulated environment. The anti-static carbon core filament yarn market is no longer a niche—it is a compliance-led, high-growth materials segment central to the automation era.

Key Players Profiled

Toray Industries | SGL Carbon | Hexcel | Hyosung TNC | Taekwang Industrial | DowAksa | Jiangsu Hengshen | Bekaert | Acelon Chemicals & Fiber | Arrow Technical Textiles

Explore trends before investing – request a sample report today! https://www.futuremarketinsights.com/reports/sample/rep-gb-31847

Browse Related Reports

Antimicrobial Copper-Infused Filament Yarns Market: https://www.futuremarketinsights.com/reports/antimicrobial-copper-infused-filament-yarns-market

Conductive Yarns for E-Textile Sensors Market: https://www.futuremarketinsights.com/reports/conductive-yarns-for-e-textile-sensors-market

Polypropylene Yarn Market: https://www.futuremarketinsights.com/reports/polypropylene-yarn-market

Why FMI: https://www.futuremarketinsights.com/why-fmi

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1,200 markets worldwide.

Sudip Saha

Future Market Insights Inc.

+18455795705 ext.

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.